Author: Aaron Ricadela

General Electric Co. is unveiling software for boosting its machines’ productivity and streamlining repairs, alongside deals with Danish shipping line Maersk Corp. and French energy producer Dalkia SA.

GE announced new software for power plants, drilling platforms and wind farms at an event in Berlin Tuesday. The showcase for GE’s IT know-how comes a day after the Boston industrial giant said longtime Chief Executive Officer Jeffrey Immelt would step down Aug. 1 in favor of health-care chief John Flannery, after a transition to "a high-tech industrial company" that’s increasingly selling software in addition to heavy gear.

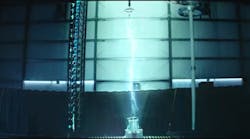

Immelt, CEO since 2001, built up GE’s capabilities in outfitting its turbines, jet engines, wind farms and medical equipment with data-collecting sensors and a software platform called Predix to analyze it all.

The software push by GE is part of a broad movement by industrial producers to create factories, energy plants and vehicles that can sense their own performance and surroundings, cut costs or create new businesses based on that data. Competitors including Germany’s Siemens AG, Switzerland’s ABB Ltd. and France’s Schneider Electric have also been adding software and data-analysis capabilities to their machinery.

Technology companies including IBM, Google, Microsoft, and Amazon.com are also applying their software to manufacturing and transportation applications, opening new rivalries.

GE has about 20,000 software engineers working on its software in the energy, aviation, healthcare equipment, and oil and gas industries. Instead of simply trying to sell service contracts with an offshore wind turbine for example, GE can now offer customers a digital model of the turbines it sells so their buyers can manage fleets based on location, performance, and weather conditions, Mark Hutchinson, GE’s CEO for Europe, said in a recent interview.

Bill Ruh, the CEO of GE Digital, the company’s software and industrial internet division, said digitizing industrial operations would constitute a $200 billion market by 2020. “As the price of their product declines, companies are looking for efficiency,” he said in an interview.

GE doesn’t plan to scale back its software push under its new CEO, vice chair Beth Comstock said in Berlin.

"Investors have been patient," she said in a meeting with reporters. "They’ve been with us the last six years as we’ve been making investments."

"I don’t know how you don’t go digital as an industrial company," she said. "John Flannery knows this first hand. He’s very aware of what’s happening in other businesses. He’s not in isolation."

GE plans later this year to introduce a combination of its software tools for monitoring machines’ performance with the ServiceMax field service software it acquired this year. GE Ventures, the company’s investment and intellectual property licensing arm, is launching a company called Avitas Systems to combine GE’s Predix platform with data analysis, robotics and AI technology for inspecting machines in the drilling, energy and transportation industries.

Maersk Drilling and GE have started a year-long pilot to increase a drilling platform’s productivity by monitoring machinery on board and predicting its maintenance schedule. GE will also work with Dalkia to predict gas engine repair schedules.

GE is estimating $1 billion in Predix orders this year, and Ruh said he’s seeing more "intensity of demand" in Europe” compared with other regions. In Germany especially a set of government programs and private investment, known as Industry 4.0, is attempting to speed up investments in digitizing production.

GE last year spent $4 billion to develop its analytical software and another $2 billion on industrial 3-D printing acquisitions and development.